Become a member

Take advantage of exclusive member benefits, world class events, networking and specialist support

Become a member

Become a member

Having devoted much time and effort to educating manufacturing companies about the ten reasons to invest in robots, we’ve decided to move things to the next level, with an A to Z list of reasons to switch to robotic automation. Why? Because we believe that 2018 will be the year that many UK manufacturers will move to catch up with their international competitors and share in the benefits that robotic automation is bringing, including increased productivity, improved quality and added flexibility.

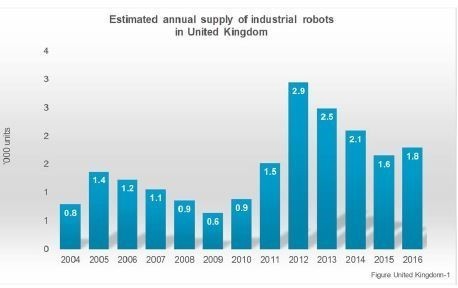

Signals for this change are coming from all directions. Over the last year, for example, we’ve witnessed more UK start-ups leading the way with smart and forward-thinking business plans incorporating robot technology. At a national level, almost 1,800 new robots were installed in UK manufacturing companies in 2016, a nine percent increase on the year before, with a total of around 18,500 robots in operation throughout UK industry.

Source: International Federation of Robotics: World Robotics – Industrial Robots 2017

Added impetus for further growth in robot adoption will hopefully be imparted by the recent launch of the UK Government’s long-awaited Industrial Strategy which urges UK manufacturers to help ‘build a Britain fit for the future’ using digital technologies. While much still needs to be done to deliver and realise this message, the launch of the strategy provides an encouraging sign of the Government’s appreciation of the importance of the nation’s manufacturing industry.

Also encouraging are the tentative signs of an upturn in the UK’s productivity. Having languished in the doldrums since the downturn of 2009, economic output per hour worked in the third and fourth quarters of 2017 increased by 0.9% and 0.8% respectively. It would be good to think that at least some of this improvement may have resulted from the increased uptake of robots.

This blog is the first of a series in which we will be looking to build on these promising signs by quite literally spelling out the ways that robots can help to transform the fortunes of UK manufacturing.

Imagine that there was a way for UK productivity to overtake the current world leaders in under five years. Picture a UK manufacturing industry in which goods are produced quickly and efficiently, and where companies can respond quickly to changes in customer demands with little or no disruption. Imagine a highly-skilled, adaptable workforce using the latest in advanced technologies, with workers able to produce more goods in fewer hours.

All of this is achievable – however, getting there will require a change of mindset, not least in the way that companies invest in new production technologies. That take-up of these production technologies lies at the heart of improved economic performance is evidenced by the performance of other countries such as China, the USA and Germany, all of which have found at least one of the answers to improved productivity – robotic automation.

Take a look at our video below showing just some of the ways that robots can be deployed to help boost productivity.

Comparing your own performance against those who do things better is never a bad place to start when setting yourself a target. When it comes to finding ways for the UK to improve its productivity, a useful benchmark for measuring our performance can be found in a study of automation, labour productivity and employment by Copenhagen Business School. Comparing the UK to other countries from around the world, the study found that if we were to become as automated as the world’s most automated countries, such as Japan, Germany and Sweden, our productivity would increase by 22.3%. Not only that, but the improvements would help to yield a projected increase in employment of at least 7.4% as new jobs are created to keep pace.

Take a look at the diagram below, which shows the productivity change that could be achieved in the UK if we were to match the most automated countries. You can find out more about the study here.

With the rest of the world adopting robots in ever greater numbers, gaining the advantage over your international competitors is increasingly going to be about who can do things faster, more efficiently and at the lowest cost. In installations worldwide, robots are already helping businesses of all sizes to produce a greater range of goods in less time and at a reduced cost, with savings stemming from areas including improved utilisation of labour and reduced wastage.

In many cases, these savings have helped companies to reduce their overall production costs to more closely match those of their competitors in low cost countries.

For UK manufacturing to keep pace it’s going to require us to greatly increase our uptake of robots. The chart below shows how the UK is currently lagging behind much of the rest of the world when it comes to robotic automation, especially China, where over 80,000 new robots were installed in 2016 alone.

Much of the reason for the UK’s low take-up of robots can be attributed to misconceptions around complexity, cost and the suitability of robots for low volume processes.

In fact, modern robots are easier to install, operate and maintain and can deliver an attractive return on investment by making both your processes and your staff more efficient and productive. Robots can also be quickly reconfigured to handle multiple processes, making them ideal for handling production runs of all sizes, even down to single units.

To find out how robots could help you to transform your competitiveness, take a look at our 10 reasons to invest in robots guide.

You can also sign up for our Switch to Robots events, which provide a step-by-step guide to introducing robots into your business.

The International Federation of Robotics (IFR) measures robot density worldwide every year and publishes a report called ‘World Robotics’. In 2016 the UK ranked fifteenth compared to other European countries, with just 71 robots per 10,000 employees.

Compare our robot density with Germany, which has 309 robots per 10,000 employees, and the need for us to catch up becomes clear.

While many people believe that increasing our take up of robots will mean a loss of employment, experience shows that the opposite is actually the case. Taking the example of Germany, when compared to the United Kingdom, its unemployment rate was 3.8% in 2017, compared to 4.7% in the UK (International Labour Organisation, ILOSTAT database). This indicates that Germany’s high robot density did not reduce employment, in fact it may have helped to improve it.

This point is further supported by looking at Jaguar Land Rover in the UK, which, despite having a heavily automated production line, has created thousands of new jobs in everything from manufacturing through to design.

Even in smaller companies, using robots to handle previously manually-intensive processes is freeing up staff to work in new areas and on new products.

Our next blogs will explain more of the benefits that can result from making a switch to robots and how the latest advances in technology are helping to reduce the complexity, time and cost of integrating a robot into your process.

E-H : http://bit.ly/E-HRobotGuide

I-L: http://bit.ly/I-LRobotGuide