Become a member

Take advantage of exclusive member benefits, world class events, networking and specialist support

Become a member

Become a member

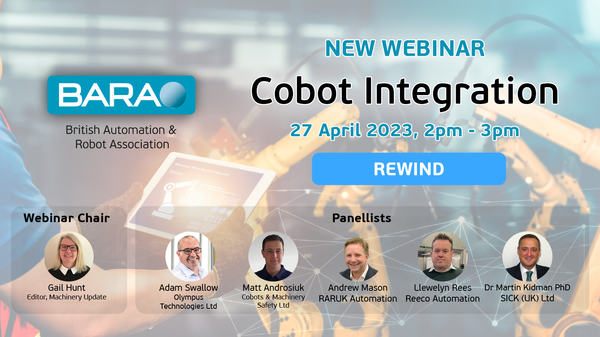

This webinar hosted by BARA has been organised to discuss the most suitable applications for Cobots, good working practices, the safety considerations involved, and provide other insightful hints and tips.

Benefits of Cobots

Collaborative robots, or “Cobots”, as they are often referred to, could potentially transform the man–machine relationship. Cobots are generally available at a lower cost than traditional industrial robots, easy to install and program, provide high levels of flexibility and can work alongside humans whilst remaining safe.

In the webinar, our panel of experts will examine the most suitable applications for Cobots, how Cobot and human operator can work together safely and efficiently, while sharing the same workspace, and how to use the Cobot's own safety features to safely restrict movement, force and speed.

Discussion Topics

You can now watch the full video of the BARA Webinar below.

Machinery Update is the official publication of the PPMA (Processing and Packaging Machinery Association). Launched in 1989, Machinery Update has developed an unrivalled reputation as the prime source of information amongst buyers and specifiers for the processing and packaging industry as a whole.

Adam is an owner and Director of Olympus Technologies, an experienced robot and cobot integrator, offering both off the shelf and bespoke robotic automation solutions to customers across multiple sectors. With Adam’s background in process improvement, he is often the first member of the Olympus team to meet potential customers, to understand their challenges and to propose solutions. He often finds himself looking at the upstream and downstream processes in order to ensure that any investment in automation is money well spent, and to ensure that it is going to create a tangible benefit for the customer. Adam is a passionate advocate for automation, but also for collaboration between suppliers, a lesson he learned from the Covid lockdown, and a lesson which serves Olympus and its customers well in 2023.

Andrew was elected to the BARA Council in 2013. With a background in Mechanical and Production Engineering, Andrew currently holds the position of Sales Manager at RARUK Automation – a specialist supplier of innovative automation products, from industrial robots, linear axis systems and feeding solutions. He is also a member of The Institute of Engineering Technology (IET).

Martin was elected to the BARA Council at the end of 2022 as a General Member Representative. He is an experienced engineer with a Ph.D. in Electrical Engineering and Electronics, is a Functional Safety Engineer (TUV Rheinland) and qualified to deliver the TUV (Saar) Engineers course. Martin has 20+ years’ experience in Industrial Engineering specialising in Functional Safety and is a recognised Functional Safety expert for Robotics and AGV/AMR applications at SICK and the BSI (Standards Committee member). As UK Product Manager for all SICK safety products, systems and services Martin has a deep passion for Safety and Automation.

There are none, a project involving a cobot, or as I prefer to say a robot designed for collaborative robot applications should be treated with as much due diligence and approached in the same manner as any other machine.

Yes, and if you need more power, speed, torque etc. then maybe a Cobot is not appropriate.

We are not saying a cobot is more appropriate than an Industrial robot; it is just another option for applications that may present benefits for particular applications around price, usability, ergonomics etc.

Discuss popular applications and encourage to pick simple application first – get good training.

A one person SME can benefit and it is not considered beyond their reach. Again, they need to choose the right application and start simple.

I could potentially see cobots being used for some repetitive/dangerous tasks for example washing down hire equipment after it has been used, welding, grinding or sanding, demolition etc. Or they could be used for consistency, like mixing, applying or building.

If a Cobot needs guarding a much as a traditional robot then that’s what it requires, risk assessment defines this. H&S managers should never be convinced otherwise for any financial benefit. However, if a Cobot allows for less guarding because of the application and the use of power and force limiting collaborative methods; then the benefit can be greater interaction, better ergonomics, higher productivity and higher flexibility.

The new version of ISO 10218-2 will incorporate safety requirements for collaborative applications (formerly, the content of ISO/TS 15066, clarify requirements for functional safety and contain requirements for cybersecurity.

A: Plus, engage with the H&S department at the initial stages to educate on the benefits and considerations.

Generally 20kg is the upper end of payloads, however some brand do offer higher payloads. Other factors can be more important to consider including reach.

Larger companies do have their own preferred guidelines when it comes to machine automation, with certain functions being used, or specific hardware being supplied. With cobots being relatively new, some larger companies are exploring the market to determine what each cobot manufacturer offers and this will then determine a path moving forward with their guidelines being updated accordingly. As mentioned in the answer to question 8, larger companies have knowledge of the safety requirements and this is placed into the guideline documents where they would expect to see risk assessment and validation documents to ensure the application is safe. It is important to request these documents from the company at the beginning of the project.

A cobot is just another type of robot, like we have delta, SCARA or 5 axis. A cobot, if used safely, can be utilised in any industrial application. You would need to assess the suitability and cost effectiveness.

Yes, every time you reprogram or move a robot, it is a new machine. Safety-related parts of the control system should have parameters that can not be changed unless the authorised password is entered. Operating instructions should also be very clear. If the customer plans to redeploy, they should have a process for re-validation by competent persons.

People also falsely believe that speed of 250 mm/s is a “safe slow speed”. This is only the maximum allowed speed when in reduced speed mode. The actually allowed speed can also be less than this and even be 0 mm/s i.e. stationary. Risk Assessment defines the speeds.

A: Using your example of palletising, the vast majority of risk assessments for cobot palletising applications will identify the requirement for additional safety, due to the typical cycle times required for a production environment (height/speed of robot arm, force/trapping hazards). The number of cases being palletised per minute is not a good indicator of safety requirements, and certainly 5-6 cases per minute cannot be assumed to be collaborative. The choice of guarding will dictate the overall footprint of your cell, for example fixed walls and light guards typically require a smaller footprint than an open cell with laser scanners.

Deploy time is dependent upon application, but it could be within a few days if simple and safety assessments can be achieved easily. Typically cobot programming training is two 2 days.

There are already lots of examples of Autonomous Mobile Robots moving large machinery:

SICK and MasterMover – Safe Starting Points for Industry 4.0 | SICK

AGV at Toyota Motor Manufacturing | Case Study - MasterMover

BASF optimizes logistics at Ludwigshafen site - YouTube

SEAT implements self-driven robots to automate outdoor parts transport - YouTube

Cobots often have built in force sensors, or if not included can be integrated at the tool flange. For material removal applications force can be used to control the amount of material by setting the applied force and is also combined with time. The cobot can carry the tool for example and orbital sander or carry the component to the sander, polishing wheel / deburring tool. As with manual material removal it is either a judgement to decide if the desired result is achieved. Alternatively, the component needs to be measured / inspected against a known “master”.

Measurement could be utilising cameras or mechanical gauging, these can be incorporated into a programming sequence to achieve the desired results. Programming for this would be more specialised than typical cobot applications.

ISO 12100 defines Risk Assessment and Risk reduction, there is also a lot of information online about the benefits of cobots. Many suppliers also provide safety documents, and there are social media blogs that can be followed, for example:

Collaborative Robot Applications in Industry | LinkedIn

In a palletising application, providing the centre of gravity of the payload is directly under the robot flange, then the allowable case payload is simply the maximum payload of the robot minus the mass of the gripper being used. The number of cases being picked is not a factor providing they are picked in such a way as to not change the centre of gravity. For example, 6 light cases could be picked together, and some palletising solution offer this flexibility.

Same question as Q18

This could be possible, as with the Q16 determining the success of the process need to be measures or compared to a known good result. Cobots can and are often incorporated with vision sensors.

This depends on the person programming the robot and the application being created. The cobot programming platform has redesigned the approach to robots and to some extent, removes the need of a high-level robot programmer and opens up the opportunity for smaller businesses who do not have the budget to spend with system integrators or machine builders. This allows quicker deployment where basic applications are required. Some cobot manufactures have both available, where teach functions and timeline functions allow for basic setups, but if more in depth programming is needed, the tablet teach pendant can be unplugged and a traditional teach pendant can be connected.

As with all automation project not just cobots a well defined and detailed URS is important.